Cold working of optical glass is a method of chemical vapor heat treatment. And monolithic sodium calcium silicon glass to change its original molecular structure without affecting the original color and light transmittance of the glass, so that it can reach the super hardness standard, under the high temperature flame impact to meet the requirements of the super hardness fireproof glass and its manufacturing method, special equipment.

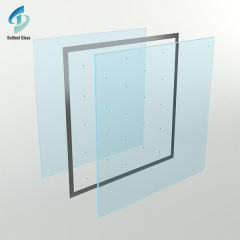

Optical glass cold working, made of the following weight ratio of components: potassium salt vapor, argon, gaseous copper chloride, nitrogen. It contains the following process: sodium calcium silicate glass as the substrate for cutting, fine grinding edge cold processing → the cold processing of sodium calcium silicate glass chemical vapor heat treatment → the sodium calcium silicate glass surface for fire protection film treatment → the sodium calcium silicate glass surface for special physical toughening treatment. The special thermal decomposition gasification equipment is composed of the cylinder body and the cylinder head and the reaction kettle connected with the cylinder head.

The cold processing of optical glass can be divided into the following categories:

1. Inlaid glass 2. Chemical etching 3. Tool engraving (all kinds of grinding wheels, sand bar engraving, crystal carving knife, computer lathe) 4. Sandblasting engraving (hand-etched paper mask, machine-etched paper mask, Photolithography mask, paint texture mask) 5. Laser engraving 6. Cutting modeling (knife cutting, water cutting) 7. Paste modeling (plane paste, space paste, paste of colored glass and film, colored beads/sand/ 8. Vertical line (vertical color crystal, vertical line paint relief shape) 9. Color painting (airbrush painting, brush painting, silk screen color drawing, polycrystalline) 10. Coating / Mirror plating (including mirror painting) 11. Ice flower (physics, chemistry) 12. Interlayer (En film interlayer: pattern cloth, flower paper, color film, wire mesh, etc.) 13. Spray paint 14. Silk screen printing, generally called screen printing. 15. Silver washing / film washing, this process is the opposite process of coating / mirror coating.

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Strength and Versatility of Thick Glass Sheets

The Strength and Versatility of Thick Glass Sheets