Good quality dimming glass has excellent light transmittance when energized, clear and transparent, beautiful appearance and light transmittance when disconnected and opaque, which can protect privacy very well. Simple test method: put the palm on the back of the glass, under the state of power, from the front to see the back of the palm, although you can see its fuzzy figure, but must not see the palm of the fingerprint. Or an object can be placed according to the front glass 10cm, in the two sides of the light balance and not a backlight, a strong light, from the opposite side, should not see the object is better. Generally good quality dimming glass transmittance should be above 74%.

For the dimming glass used for bathroom partition, exterior and interior curtain walls, doors and Windows and other non-indoor purposes, the manufacturer should ask whether the dimming glass intermediate film is EVA layer interlayer or PVB layer interlayer. When purchasing the dimming glass, the manufacturer can ask for the certificate of intermediate film to prove whether EVA film or PVB film is used. Curtain wall glass and laminated glass used in outdoor applications generally do not use EVA film as the intermediate film, because EVA is very easy to yellowing, aging and even delamination under the conditions of sun exposure or high temperature and humidity; In addition, due to the poor inherent viscosity of EVA, the safety index of laminated glass products such as the anti-impact strength is low, so it is generally abandoned by curtain wall operators.

Consumers can choose according to the requirement of the applications of functional glass using the corresponding glass panel, such as higher requirements for safety coefficient of public buildings, and the application of bathroom and outdoor curtain wall area should be chosen as the dimming glass panel, toughened glass for fire prevention demanding customer can choose fireproofing glass panel, applied to the need to bend to choose curved glass panels, etc.

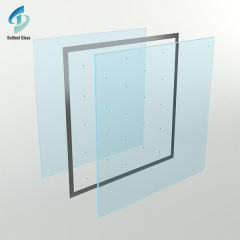

If the dimming glass needs to be hollowed out and fixed, we should ask the manufacturer in advance to see if we can dig holes, because the general manufacturers or new manufacturers, most of the way to meet the requirements, so ask to see if there is relevant experience or can do to avoid some unnecessary trouble and loss.

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Strength and Versatility of Thick Glass Sheets

The Strength and Versatility of Thick Glass Sheets

Breaking Boundaries: The Evolution and Applications of Ultra Thin Glass

Breaking Boundaries: The Evolution and Applications of Ultra Thin Glass