Optical glass is a glass material used in the manufacture of lenses, prisms, mirrors, Windows, etc. of optical instruments or mechanical systems. There are many kinds of optical glass, including colorless optical glass, colored optical glass, laser glass, radiation resistant optical glass, radiation protection optical glass and optical quartz glass and other categories.

The stripe produced by ordinary glass is mainly because the compound is not uniform; Corrosion of refractories; From agitation in the making of glass.

Therefore, optical glass should start from these aspects. Optical glass requires pure raw materials, impurities are less than one hundred thousand parts, and the particle size of raw materials, and the amount of weighing has very high requirements. Molten glass should be stirred. According to the characteristics of different glasses, crucible melting, continuous melting, high-frequency melting and other methods can be used. The forming process can be broken pot, pouring, rolling, dropping, liquid suction, pressing and other technologies. In order to ensure the optical uniformity, annealing is very critical and strict. Optical glass is mostly used in telescopes, microscopes, cameras, sights and other optical instruments as lenses, prisms, mirrors and other optical components.

In addition, the structure of the furnace is not the same as the daily glass furnace, it is divided into melting pool (feeding), regulating pool (regulating melting atmosphere), refining pool (clarification), homogenization pool (stirring), large furnace daily output is generally only 5 tons.

Colorless optical glass is often referred to as optical glass, is a broad category of optical glass, and corona glass and flint glass two categories and a dozen small categories, about more than 200 grades. Each grade must have specified optical constants and optical homogeneity, transparency and chemical stability. Some optical glasses also require special dispersion.

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

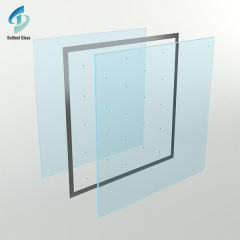

The Strength and Versatility of Thick Glass Sheets

The Strength and Versatility of Thick Glass Sheets