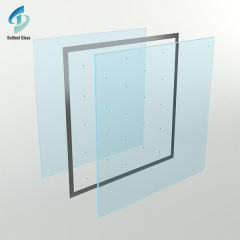

The hollow glass processing equipment we make can complete the production of hollow glass efficiently and with high quality, and enjoy a high reputation in the hollow glass processing industry. All equipment in the factory has its own operating procedures. When operating the hollow glass production line, the operator must strictly abide by the operating rules of the energy-saving hollow glass processing equipment. What are the operating rules of the hollow glass processing equipment, please note:

1. Start-up sequence of the hollow glass production line: First, check whether the water in the water tank of the hollow glass processing equipment is sufficient, then turn on the water pump, adjust the nozzle above the white cotton roller, and ensure that all positions of the roller are cleaned. Then wash the impurities and dirt on the sponge roller by hand, and ensure that the sponge roller is fully foamed and expanded. It is recommended that when opening the insulating glass production line in winter, the cleaning transmission must be turned on first. Because the two adjacent sponge rollers will freeze together in winter, and the transfer process is not soaked in water, the sponge rollers will be torn.

2. Turn on the cleaning conveyor again, and place the hollow glass to be processed on the conveyor wheel. Pay attention to the smoothness of the glass to prevent the glass from falling and hurting people during transmission.

3. The aluminum spacer is coated with butyl glue to ensure uniformity and apply it to the entire surface of the aluminum strip to prevent glue leakage and burrs. And use high quality butyl glue to make sure the aluminum bars stand firmly with the glass. After the aluminum spacer is glued, no sticky dust is allowed.

4. The two-component seal should be firmly coated, and the surface should be kept smooth, especially at the corners to prevent air leakage and escape.

The precautions for the use of the above-mentioned equipment for processing hollow glass must be strictly observed.

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages