Sandblasted glass, is a water mixed emery, high pressure injection on the glass surface, in order to polish a process. Including spray glass and sand carved glass, it is the automatic horizontal sandblasting machine or vertical sandblasting machine on the glass processed into horizontal or concave carved pattern glass products. Color can also be added to the pattern called "spray glass", or used with the computer engraving machine, deep carving shallow carving, forming a dazzling, lifelike fine art.

Sandblasting is a kind of compressed air as the power to push abrasive to the surface of the workpiece is called sand blasting, which is often said that shot peening cleaning, shot peening processing. Because sand was the only abrasive available in the early days of shot blasting, shot blasting was called sand blasting at that time and for a long time afterwards.

Sandblasted glass is mainly used in indoor partition, decoration, screen, bathroom, furniture, doors and Windows, etc.

In a variety of surface pretreatment methods, sandblasting (shot peening cleaning) the effect of the most thorough, the most adaptable, the widest range of applications, this is because the steel surface cleaning fastest, the most thorough; Only sandblasting can be assessed by four universally acceptable levels of cleanup; Sandblasting can clean surfaces that are usually difficult to clean, and some special tools can be used to clean the inner surface of the pipeline, and the cost of sandblasting is the lowest.

Sandblasted glass mainly plays the role of blocking light, softening the light and playing a decorative role. Sandblasting and sandblasting are just different processing methods, and the effect achieved after processing is the same.

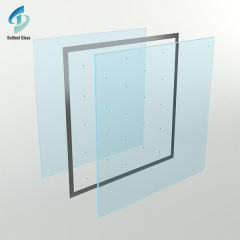

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Strength and Versatility of Thick Glass Sheets

The Strength and Versatility of Thick Glass Sheets