When quartz glass is used at high temperature for a long time, it will produce opaque cristobalite crystal, which is the so-called crystallization phenomenon. At the beginning of the isolated white crystallization point, with the extension of time, the crystallization point increased and grew up, connected into a piece, and extended from the surface to the interior, so that the quartz glass is completely impervious, this method is to keep the sample at high temperature, constant temperature for a certain time, the thickness of the glass surface impervious layer.

1. Preparation of quartz glass test

For the quartz glass tube with an outer diameter below 25mm, three sections of the whole tube sample with a length of 15mm were cut.

Outside diameter of more than 25mm quartz glass tube out of the string length of 25mm, length of l5mm sample two pieces.

Cut quartz glass crucible radian part and quartz glassware use parts of 25mmX15mm sample three pieces.

The above samples are the original wall thickness, the surface is not processed, the sample incision with emery ground, can not have a collapse mouth.

2.Quartz glass crystallization test equipment:

Electric heating drying oven, a vertical high temperature molybdenum disilide electric furnace, the electric furnace must have a double furnace, the furnace is made of high purity aluminum oxide material, the furnace sample table is placed with quartz pad, a measuring microscope: the measuring accuracy is 5μ, the magnification is 100.

3.Quartz glass crystallization test steps:

Soak in 10% chemically pure hydrofluoric acid solution for 15 minutes, take out and rinse with tap water for 15 minutes, and then rinse twice with deionized water. The cleaned samples were taken out with clips and dried in a dry petri dish lined with clean gauze. Do not touch the sample directly with your hands during the entire operation to prevent contamination.

Put the clean samples into a high temperature furnace with a constant temperature of 1400℃ for 6 hours. The furnace door is then immediately opened and the specimen is removed with clean crucible tongs. Allow to cool slightly and place in a mixture of protective paraffin and rosin.

The crystallization layer at both ends of the sample is ground off with emery and polished. Wash the protective wax off with gasoline.

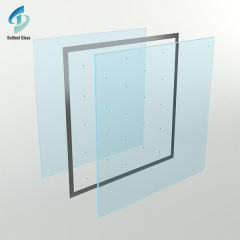

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages