For the production method of stained glass, the first step is to prepare the color drawing. It is better to use watercolor or ink to make the drawing closer to the artistic effect of glass.

Step 2 Enlarge the artwork. After the color drawing is completed, enlarging the sketch is the second step of production. The enlarged drawing must be exactly the same size as the actual production.

Step 3 After confirming that the enlarged mosaic of the lead bars has been completed, the next step is to draw the mosaic artwork, which involves drawing the lines of the lead bars on the magnified draft.

Step 4 Free choice of glass if the mechanism of glass and the free choice of color is wrong, the final stained glass will not achieve the desired effect.

Step 5 Cutting glass when we freely choose glass after the glass needs to be cut into shape, according to cut transparent paper cutting. It must be cut precisely, and to save material.

Step 6 In the whole painting, some parts must be hand-painted raw materials, such as the face, hands and other hand-painted parts need to be put into the kiln for several times to fire the painted glass, we put it into the furnace to fire.

Step 7 Inlay glass after we finish baking glass, use lead to make small pieces of glass to join together, lead has many kinds of shape, thickness is different, soft, hardness is different, according to different must be used.

Step 8 Insert putty whole glass inlay. After soldering. The next step is to embed putty. The putty was diluted with tung oil and embedded in the gap between the lead strip and the glass to make it stable. And strengthen the thickness of the lead. Sharpen the color. To mix glass and lead.

Step 9 repair Mosaic glass skeleton glass has been completed, before installation, it is necessary to consider its fastness, wind tolerance. So wire is welded at some points so that it can be tied to the iron bars on the window frame in the future. This step needs to consider its point placement when making the enlargement.

The 10th step stained glass installation, installation of a variety of types, complex, ceilings, light boxes, Windows, screens, doors, curtain walls, etc., are installed in the wood frame iron frame, etc.

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

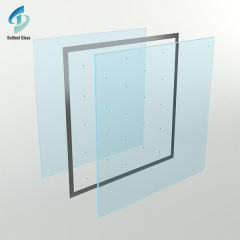

The Strength and Versatility of Thick Glass Sheets

The Strength and Versatility of Thick Glass Sheets