Birth of bulletproof glass

When French chemist was sorting chemicals in his laboratory, he was intrigued by a medicine bottle accidentally dropped on the ground.

Because the medicine bottle made of glass was not broken, but crisscrossed cracks appeared on the wall of the glass. So he began to study the medicine bottle and found that the medicine bottle was filled with a solution of nitrocellulose resin. After the solution volatilized, a film was formed on the surface of the glass bottle. Completely turned into rubbish. This discovery brought inspiration to nenadites, and after many experiments, he finally developed the world's first safety glass, which is also the predecessor of bulletproof glass.

Glass structure

From the outside, bulletproof glass is no different from ordinary glass, however, this is only an appearance. Bulletproof glass can block the attack of one to several rounds of bullets, while ordinary glass, let alone bullets, can shatter the glass with a single blow of a hammer. So what gives bulletproof glass its super resistance?

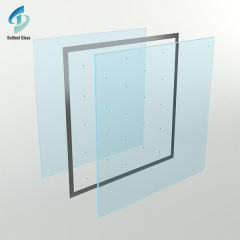

Bulletproof glass is actually made of multiple layers of glass and high-strength organic materials glued together under high temperature and pressure. It is generally composed of three parts: bearing layer glass, transition layer material and protective layer glass.

Bulletproof glass is a combination of glass with a layer of glue sandwiched inside. The glue of the middle transition layer is generally PVB (polyvinyl butyral), which is the best glass bonding material in the world. It has the advantages of good adhesion and high mechanical strength, and has a certain degree of flexibility. Capable of absorbing most of the energy generated during bullet impact. This stops the bullet from continuing to penetrate the inner glass. Some manufacturers also use materials such as polycarbonate.

When the glass is shattered by bullets, most of the resulting fragments will adhere to the surface of the transition layer, and there will not be a large number of fragments flying.

Outer glass

The bulletproof ability of bulletproof glass depends on the thickness of the outer glass. The thicker the glass, the higher the strength and the greater the impact force it can withstand. Therefore, the bulletproof glass that defends against rifle bullets is much thicker than the bulletproof glass that defends against pistol bullets. .

The purpose of the outer bulletproof glass is to deform the bullet and change the direction of the bullet, so that it does not have the penetration force to continue inward. Generally, high-strength special glass is used.

Inner glass

The inner glass needs to be made of special glass or plexiglass with better elasticity and toughness. The purpose is to ensure that the remaining energy of the bullet will not penetrate the bulletproof glass.

Today's bulletproof glass is generally composed of multiple layers of glass and multiple interlayers, and the interlayer will also add some other materials according to the application scenario.

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages

The Beauty and Utility of Thin Glass Sheets: Applications and Advantages