The glass substrate is the upstream core component of the liquid crystal panel. In terms of cost composition, the two glass substrates account for about 15%-20% of the cost of the entire panel. The cost of glass substrate is not the highest, but it is the most difficult and technical part to produce.

|

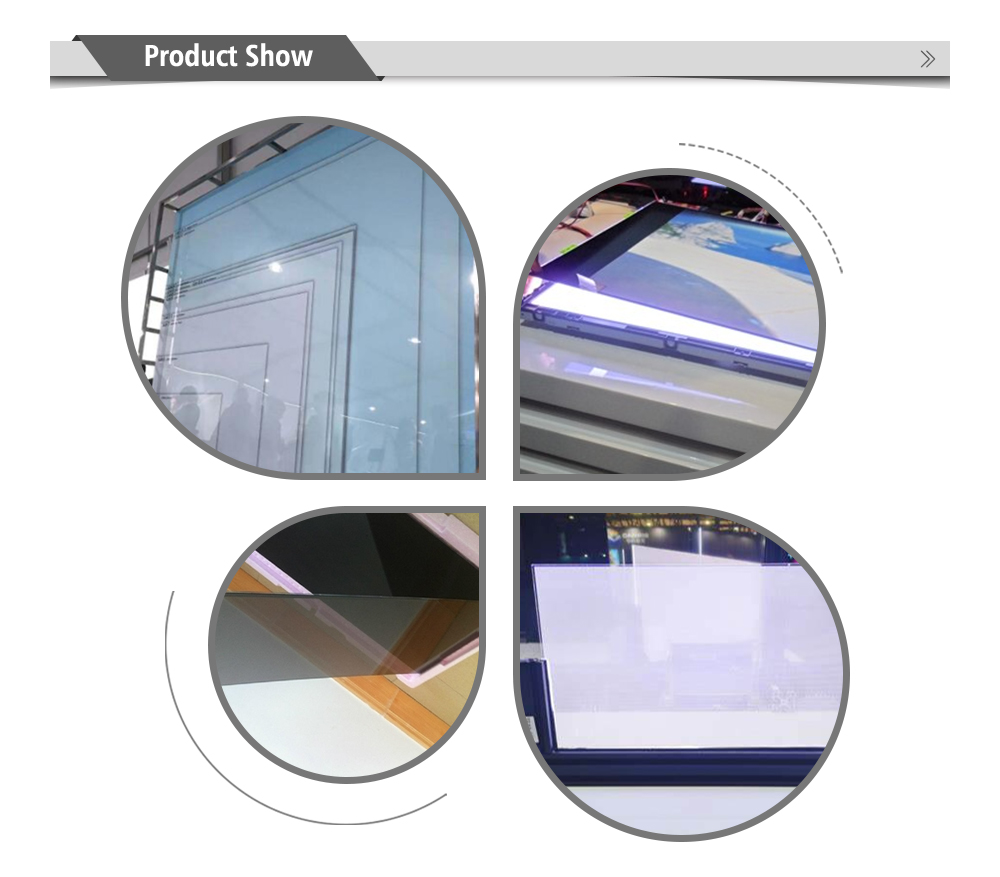

Product Name |

Glass substrate |

|

Specification |

According to customer requirements |

|

Transmittance |

91.2%-91.8% |

|

Transparency |

Super transparent |

|

Shape |

Can be produced according to customer requirements. |

|

Processing |

Polishing; Cornering; Chamfering; Drilling, etc. |

|

Application |

Construction, furniture, home appliances, electronic instruments, automobile manufacturing, etc. |

|

Pricing Term |

EXW,FOB,CIF,CFR,CNF, etc. |

|

Payment Method |

T/T, Western Union, L/C, etc. |

|

Package |

Standard seaworthy export packaging. Glass outer packaging: EPE, EPS, plastic corners, carton, plywood box, etc. Fixed: plastic packing belt, steel packing belt, etc. According to customer needs. |

|

Standard |

CE, BSI, SGCC, CCC, ISO9001, EN12150, AS/NZS2208:1996, etc. |

|

Export |

United States, Australia, South Korea, UAE, Italy, Poland, Germany, Thailand, Iran, Israel, etc. |

"Ultra-thin, heat dissipation, high-density drive" is the most widely mentioned advantage of glass substrates. However, this is not the full advantage of glass substrates.

Glass substrate is one of the necessary components for liquid crystal panels. One liquid crystal panel needs two glass substrates, which are used as the bottom glass substrate and the color filter substrate respectively.