Float glass is treated with tin, and the product is relatively uniform and flat under the action of surface tension. It is one of the most widely used glass materials. Float glass is very common in the construction field and can be further processed to be used as raw materials for other products.

|

Product Name |

Float glass |

|

Normal Thickness (mm) |

1.8, 2.0, 2.5, 2.7, 3.0, 3.5, 4.0, 4.5, 5.0, 6.0, 8.0, 10.0, 12.0, etc. |

|

Normal Size (mm) |

1220*2440, 1600*2440, 1830* 2440, 1900*2440, 2000*2440, 1830*2000, 1830*2200, 1700*2440, 1900*2200, 2440*3660, 2134*3300, 2134*3660, 2440 3300 etc. |

|

Color |

Transparent and clear, white, ultra clear, blue, etc. |

|

Structure |

Hard |

|

Feature |

High strength |

|

Shape |

Round, square, rectangular, irregular shaped, etc. |

|

Transmittance |

90% |

|

Edge Processing |

Round edge; Straight edge; Bevel edge; Polished edge, etc. |

|

Deep Processing |

Tempering, sanding, bending, cutting, edge banding, etc. |

|

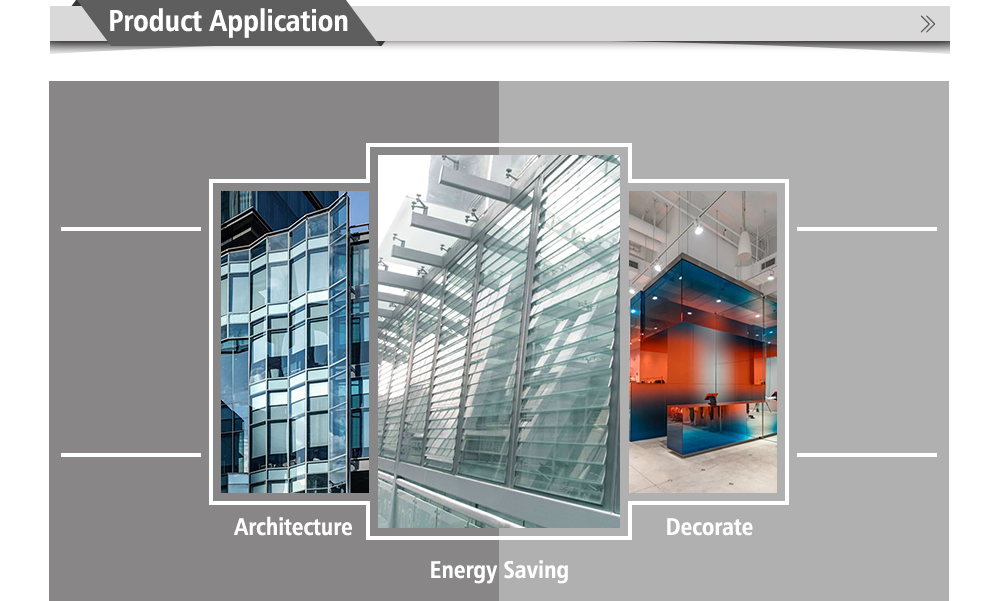

Application |

Workshop, kitchen, exterior, living room, park, hospital, hotel, etc. |

|

Pricing Term |

EXW,FOB,CIF,CFR,CNF etc. |

|

Payment Method |

T/T, Western Union, L/C, etc. |

|

Package |

Standard seaworthy export packaging. Glass outer packaging: EPE, EPS, plastic corners, carton, plywood box, etc. Fixed: plastic packing belt, steel packing belt, etc. According to customer needs. |

|

Standard |

CE, BSI, SGCC, CCC, ISO9001, EN12150, AS/NZS2208:1996, etc. |

|

Export |

United States, Australia, South Korea, UAE, Italy, Poland, Germany, Thailand, Iran, Israel, etc. |

1. High transmittance, excellent optical properties.

2. The surface is smooth and flat, and visible defects are strictly controlled.

3. Easy to cut, insulate, temper and coat.

The ultra-white float glass in float glass has a very broad application and market prospect, and is widely used in high-end buildings, high-end glass processing, solar photovoltaic curtain walls, special buildings and other fields.