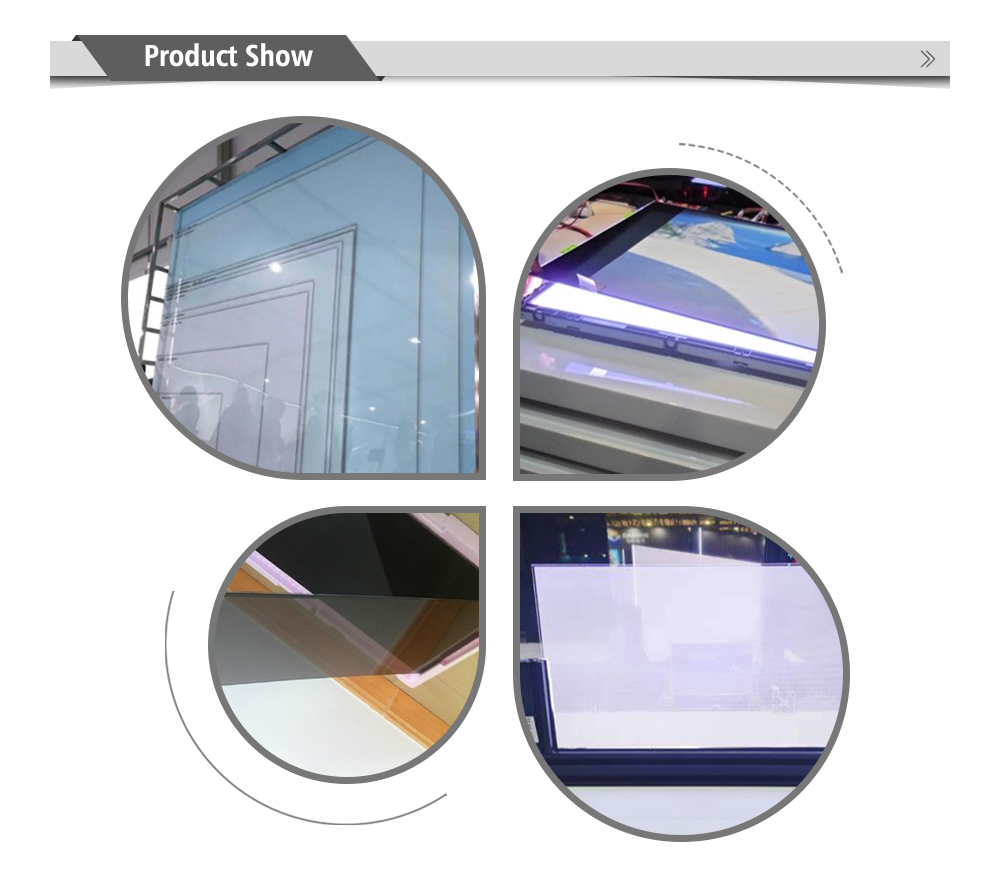

Glass substrate is a thin glass sheet produced by float method with an extremely flat surface. It is processed into transparent conductive patterns after photolithography. It is the core component upstream of the liquid crystal panel and one of the key basic materials in the flat panel display industry.

|

Product Name |

Glass substrate |

|

Specification |

According to customer requirements |

|

Transmittance |

91.2%-91.8% |

|

Transparency |

Super transparent |

|

Shape |

Can be produced according to customer requirements. |

|

Processing |

Polishing; Cornering; Chamfering; Drilling, etc. |

|

Application |

Construction, furniture, home appliances, electronic instruments, automobile manufacturing, etc. |

|

Pricing Term |

EXW,FOB,CIF,CFR,CNF, etc. |

|

Payment Method |

T/T, Western Union, L/C, etc. |

|

Package |

Standard seaworthy export packaging. Glass outer packaging: EPE, EPS, plastic corners, carton, plywood box, etc. Fixed: plastic packing belt, steel packing belt, etc. According to customer needs. |

|

Standard |

CE, BSI, SGCC, CCC, ISO9001, EN12150, AS/NZS2208:1996, etc. |

|

Export |

United States, Australia, South Korea, UAE, Italy, Poland, Germany, Thailand, Iran, Israel, etc. |

The glass substrate has high thermal conductivity, which can better maintain the stability of the panel in higher-density solder products, and can meet more complex wiring requirements.

Glass substrate is one of the necessary components for liquid crystal panels. One liquid crystal panel needs two glass substrates, which are used as the bottom glass substrate and the color filter substrate respectively.