Rolled plate glass generally has quartz sand, limestone, feldspar, soda ash, boric acid and other raw materials. Rolled plate glass forming methods can be divided into two categories: artificial forming and mechanical forming. At present, the mainstream use of mechanical forming methods for production and manufacturing.

|

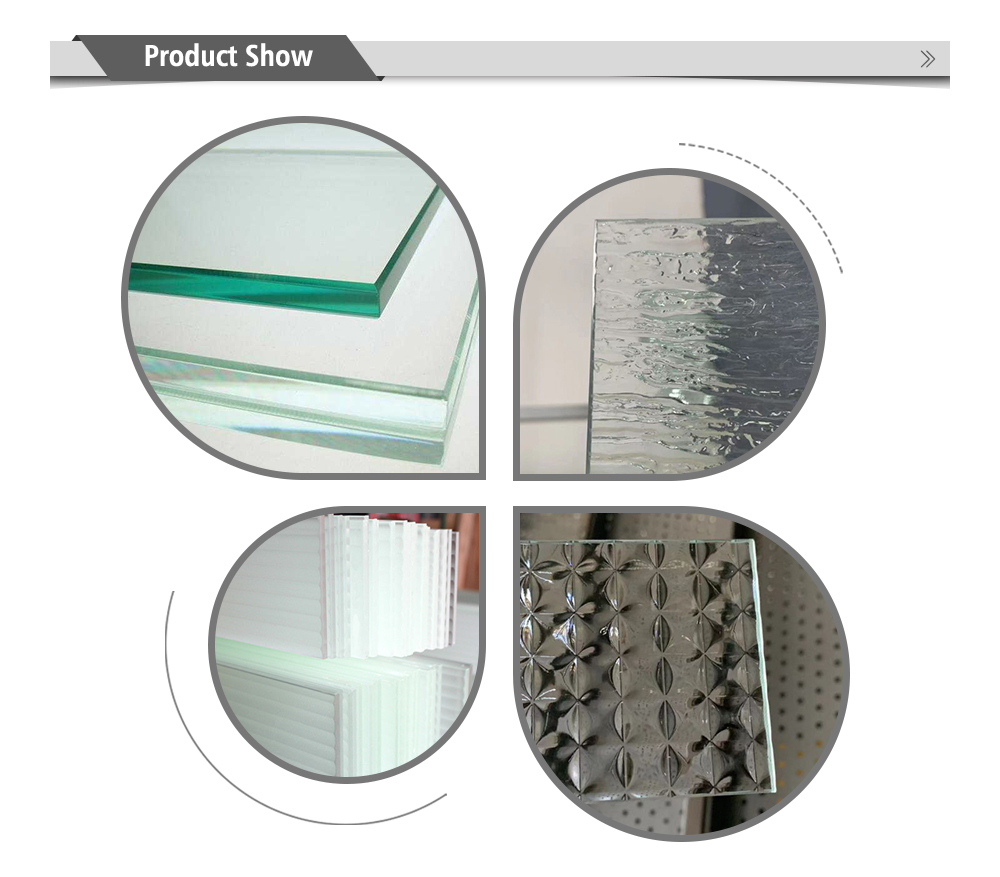

Product Name |

Rolled plate glass |

|

Material |

Quartz sand, limestone, feldspar, soda ash, boric acid, etc. |

|

Size |

1220x1830mm, 1500x2000mm, 1524x2134mm, 1830x2440mm, 2000x2500mm, 2000x3300, etc. or customized. |

|

Thickness |

3mm, 4mm, 5mm, 5.5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm, etc. |

|

Color |

Ultra clear, clear, amber, blue, green, bronze, grey, gold and more. |

|

Shape |

Flat, curved, irregular or customized on demand. |

|

Compressive Strength |

1100Mpa |

|

Processing |

Can be cut, ground, drilled, tempered, laminated and printed etc. |

|

Silicon Content |

More than 80% |

|

Delivery Time |

25-30 days |

|

Pricing Term |

EXW,FOB,CIF,CFR,CNF etc. |

|

Payment Method |

T/T, Western Union, L/C, etc. |

|

Package |

Standard seaworthy export packaging. Glass outer packaging: EPE, EPS, plastic corners, carton, plywood box, etc. Fixed: plastic packing belt, steel packing belt, etc. According to customer needs. |

|

Standard |

CE, BSI, SGCC, CCC, ISO9001, EN12150, AS/NZS2208:1996, etc. |

|

Export |

United States, Australia, South Korea, UAE, Italy, Poland, Germany, Thailand, Iran, Israel, etc. |

Rolled plate glass also has all the processability properties of high-quality float glass, and has excellent physical, mechanical and optical properties, and can be processed in various deep processes like other high-quality float glass. Unparalleled superior quality and product performance make rolled plate glass have broad market prospects.

Curtain walls, hotel interiors, railings, screens, partitions, shopping malls, churches, museums, etc.