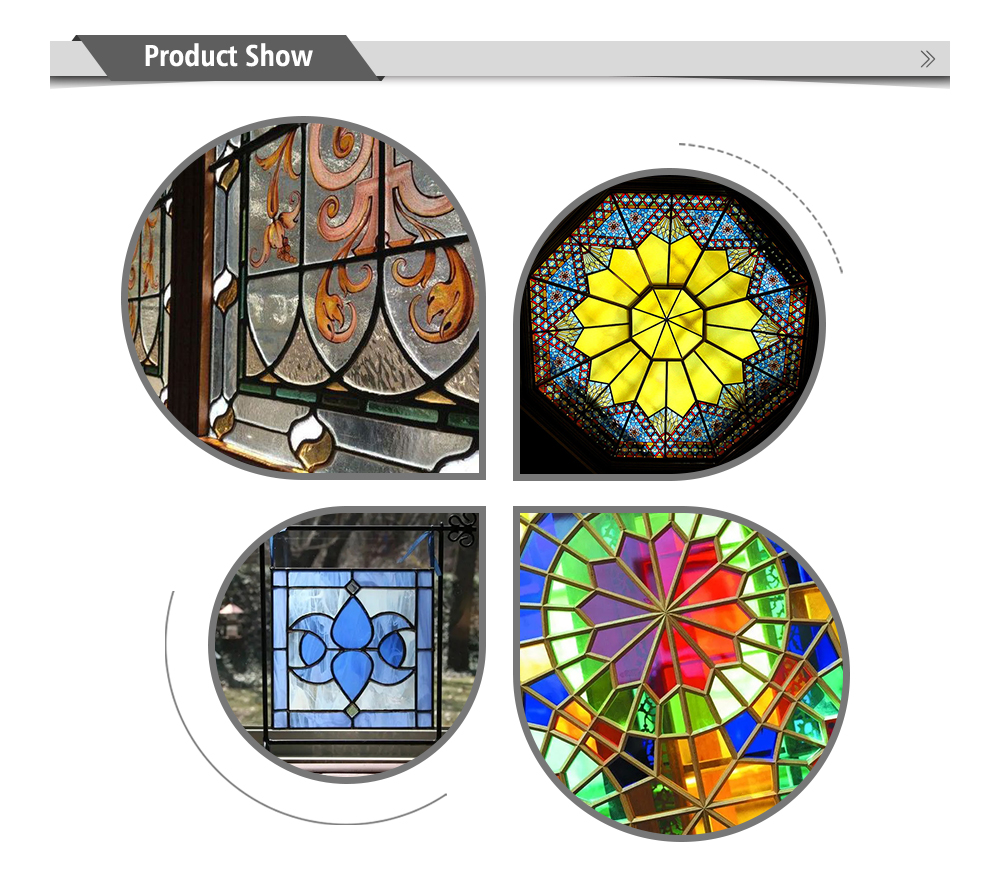

The production method of stained glass is to use glass as a canvas and use special pigments. After painting, it can be fired at a low temperature. The color will not fall off, the durability will be longer, there is no need to worry about being corroded by acid and alkali, and it is also easy to clean. Customized, the size, color and pattern can be matched at will, which is safe and more personalized, not easy to repeat, and fast to make.

|

Product Name |

Stained glass |

|

Thickness |

Normal 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, etc. |

|

Color |

Clear, white, black, yellow, orange, red, green, blue, pink, purple, golden bronze, etc. |

|

Size |

Min: 180mmx350mm, Max: 3300mmx12000mm Customized size is welcome. |

|

Processing |

Beveling, cutting, drilling, pinting, etc. |

|

Glass Pattern |

Colorful, pattern can be customized. |

|

Shape |

Support any shape customized. |

|

Pricing Term |

EXW,FOB,CIF,CFR,CNF etc. |

|

Payment Method |

T/T, Western Union, L/C, etc. |

|

Package |

Standard seaworthy export packaging. Glass outer packaging: EPE, EPS, plastic corners, carton, plywood box, etc. Fixed: plastic packing belt, steel packing belt, etc. According to customer needs. |

|

Standard |

CE, BSI, SGCC, CCC, ISO9001, EN12150, AS/NZS2208:1996, etc. |

|

Export |

United States, Australia, South Korea, UAE, Italy, Poland, Germany, Thailand, Iran, Israel, etc. |

1. Modern style, unique

2. Heat-resistant, attention-resistant and warm

3. Anti-oxidation and impact resistance

4. Withstand high and low temperature

Stained glass is mainly used in exterior and curtain walls, skylights, railings, escalators, doors and windows, shower rooms, partitions, etc.