With the rapid development of electronic information, the computer room as a CNC center of modern office, has an irreplaceable core position, therefore, in the room decoration or reconstruction project, the design and construction of the room partition wall have more strict requirements, strict selection of fire resistant glass partition is the primary choice of glass partition in the current room.

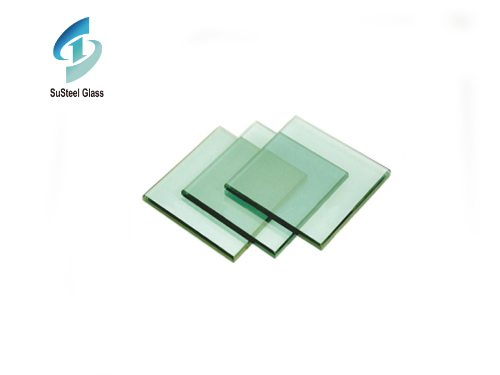

The same fire zone can use 12mm thick single toughened glass for design and construction, the frame is generally made of square steel or stainless steel.

Different fire zones can use 12mm thick single piece of cesium potassium fire resistant glass. (In addition, it should be noted that fire-resistant glass with corresponding fire-resistant time should be selected according to the requirements of the local fire department on the glass partition.) Room partition engineering In order to ensure that there is no internal column in the room, the building of the room often uses the large-span structure. Competition for the computer system of different equipment to the different requirements of the environment, easy to air conditioning control, dust control, noise control and room management, often use partition walls to separate the large room space into smaller functional areas. Partition wall should be light and thin, but also sound insulation, heat insulation.

The outside doors and Windows of the machine room are mostly fire resistant glass doors and Windows, and the inside doors and Windows of the machine room are generally rimless large glass doors, which not only ensures the safety of the machine room, but also ensures the transparent and bright effect in the machine room.

Machine room fire resistant glass partition has the following functions:

1. Warm and comfortable, improve the environment comfort;

2. Energy saving and environmental protection, significantly reducing the cost of refrigeration and heating;

3. Sound insulation and noise reduction;

Exploring the Versatility and Elegance of Custom Thick Glass

Exploring the Versatility and Elegance of Custom Thick Glass

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Unveiling the Strength and Versatility of Laminated Glass: Exploring Material Properties

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Enhancing Safety with Blast Resistant Glass: Innovations, Applications, and Protective Solutions

Painted glass has emerged as a captivating medium for interior design

Painted glass has emerged as a captivating medium for interior design